The Making Of The Lexus LFA Supercar. An Inside Report In 5 Chapters

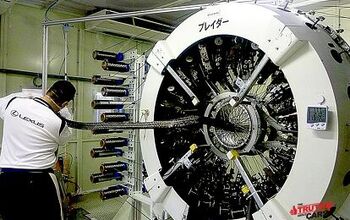

One of two circular looms on the planet. 12 layers of seamless carbon fiber are woven into what will be part T3-3RH, part A-pillar, part roof support

This 5 chapter series gives you unprecedented access to the LFA Works in Motomachi. Here, 500 LFA supercars are being handmade by 170 people, and you can watch how they do it.

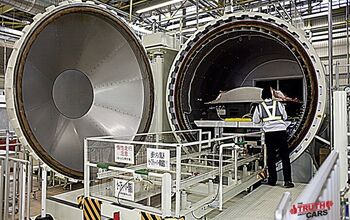

The baking happens in the autoclave next door. Picture it as a garage-sized pressure cooker. Pieces in the autoclave are covered with foil, then vacuum is applied that presses the layered piece into its mold. Two bars of pressure is applied to the autoclave, and at a constant temperature of 150 C, the parts are cooked to perfection.””

Chapter One: From A Bar To Bar None. How the LFA was born, and why it is made from carbon fiber.

The strongest parts of the LFA are made in a clean room. Our hair is covered. We wear long white coveralls. Booties go over our shoes. Someone vacuums me from top to bottom.””

Chapter Two: In The Clean Room. Where the LFA is made from the strongest and most expensive type of carbon fiber available.

Building the body of one LFA takes four days, we race through it in three hours. On the fourth day, there is what is called a body-in-white in the car making industry. Except that in the case of the LFA, it is a body-in-black. In a shiny, glossy black that we usually associate with carbon fiber.””

Chapter Three: Call Me Names. How the LFA really received its name.

Some likened the sound to “the roar of an angel”, some to “an F1-inspired tune.” Lesser poets could compare it to the sound of a circular saw.””

Chapter Four Balance Of Power. We watch the V10 engine go into the LFA.

What will happen to the LFA Works at the end of the year? Will Tanahashi, now 59, simply go into retirement? Will the 170 associates who make the LFA go back to making Crowns, Corollas and Camrys?

Chapter Five: Exam Week. We examine Chief Engineer Tanahashi about how the LFA influences future cars, and what will come after the LFA.

Bertel Schmitt comes back to journalism after taking a 35 year break in advertising and marketing. He ran and owned advertising agencies in Duesseldorf, Germany, and New York City. Volkswagen A.G. was Bertel's most important corporate account. Schmitt's advertising and marketing career touched many corners of the industry with a special focus on automotive products and services. Since 2004, he lives in Japan and China with his wife <a href="http://www.tomokoandbertel.com"> Tomoko </a>. Bertel Schmitt is a founding board member of the <a href="http://www.offshoresuperseries.com"> Offshore Super Series </a>, an American offshore powerboat racing organization. He is co-owner of the racing team Typhoon.

More by Bertel Schmitt

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Kwik_Shift_Pro4X Canadians are able to win?

- Doc423 More over-priced, unreliable garbage from Mini Cooper/BMW.

- Tsarcasm Chevron Techron and Lubri-Moly Jectron are the only ones that have a lot of Polyether Amine (PEA) in them.

- Tassos OK Corey. I went and saw the photos again. Besides the fins, one thing I did not like on one of the models (I bet it was the 59) was the windshield, which looked bent (although I would bet its designer thought it was so cool at the time). Besides the too loud fins. The 58 was better.

- Spectator Lawfare in action, let’s see where this goes.

Comments

Join the conversation

That carbon-fiber loom looks a lot like a Wright R-2600 engine on a B-25 bomber.

Astonishing stuff. The LF-A really is a no-expense spared car.