It's Decision Time for Ford's Carbon Fiber Subframe

By the end of the year, you’ll know whether your next front-drive, non-supercar Ford might contain a carbon fiber cradle for its engine. As promised, supplier Magna has delivered a carbon fiber composite subframe prototype to Dearborn, destined for a rigorous life in a Fusion testbed.

There’ll be calculators working overtime as Ford engineers and bean counters figure out whether the lightweight, parts-saving component has a place in the brand’s stable.

Magna first revealed its plans for the co-developed subframe in March 2017. While this isn’t the first time Ford tapped the supplier’s carbon fiber expertise, there’s a vast mass and price difference between the grille opening reinforcement on a pricey model like the Shelby GT500 and a subframe bound for a conventional passenger car.

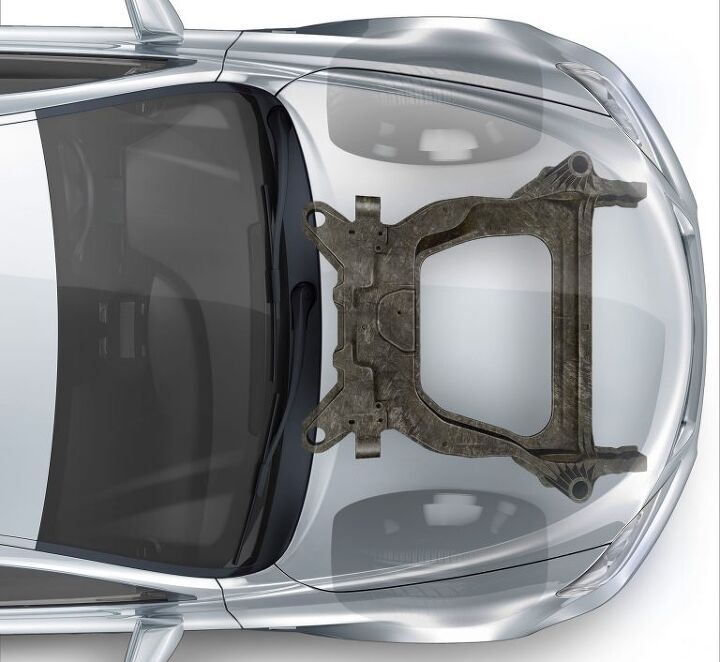

The supplier’s prototype reduces subframe mass by 34 percent over its steel counterpart. Comprising two molded and four metal parts, the structure replaces 45 steel parts found in a typical Fusion subframe.

“We delivered a series of parts to the customer at the end of last year, and they’ve already started component testing,” Andrew Swikoski, Magna’s global product line director for lightweight composites, told Automotive News. “By the end of the year, we’ll know whether the technology is ready for production or not.”

Swikoski didn’t fully break down the economics of using the pricey material, though he implied Ford customers wouldn’t see a diamond-encrusted markup on the price of a new vehicle. Using Magna’s subframe would cut tooling costs by 30 to 40 percent, he said, and Magna sought to further reduce expense by using several materials in the composite.

Crash testing could be a determining factor in whether the component gets the green light. “It’s not meant to be a primary crash absorber,” Swikoski said, adding that, as the subframe only absorbs 5 percent of a crash’s energy, Ford will rely on the subframe’s steel surroundings for cushioning.

[Image: Magna]

More by Steph Willems

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Rover Sig 2021 Jeep Grand Cherokee Limited, like my previous JGC's cheap to keep (essentially just oil, tires) until recent episode of clunking in front suspension at 50K miles led to $3000 of parts replaced over fives visits to two Jeep dealers which finally bought a quiet front end. Most expensive repair on any vehicle I've owned in the last 56 years.

- Bob Hey Tassos, have you seen it with top down. It's a permanent roll bar so if it flips no problem. It's the only car with one permanently there. So shoots down your issue. I had a 1998 for 10 years it was perfect, but yes slow. Hardly ever see any of them anymore.

- 3-On-The-Tree 2007 Toyota Sienna bedsides new plugs, flat tire on I-10 in van Horn Tx on the way to Fort Huachuca.2021 Tundra Crewmax no issues2021 Rav 4 no issues2010 Corolla I put in a alternator in Mar1985 Toyota Land Cruiser FJ60 280,000mi I put in a new radiator back in 08 before I deployed, did a valve job, new fuel and oil pump. Leaky rear main seal, transmission, transfer case. Rebuild carb twice, had a recall on the gas tank surprisingly in 2010 at 25 years later.2014 Ford F159 Ecoboost 3.5L by 80,000mi went through both turbos, driver side leaking, passenger side completely replaced. Rear min seal leak once at 50,000 second at 80,000. And last was a timing chain cover leak.2009 C6 Corvette LS3 Base, I put in a new radiator in 2021.

- ChristianWimmer 2018 Mercedes A250 AMG Line (W177) - no issues or unscheduled dealer visits. Regular maintenance at the dealer once a year costs between 400,- Euros (standard service) to 1200,- Euros (major service, new spark plugs, brake pads + TÜV). Had one recall where they had to fix an A/C hose which might become loose. Great car and fun to drive and very economical but also fast. Recently gave it an “Italian tune up” on the Autobahn.

- Bd2 Lexus is just a higher trim package Toyota. ^^

Comments

Join the conversation

Setting: Ford Dealer Service Department Service Advisor: Well sir, we found the issue with your harsh engine vibrations, you have a crack in your engine cradle. Customer: Ok, wonderful......so you can weld that right? How much will it cost? Service Advisor: Err...well....Ford decided that a 20 lb weight reduce would be a fabulous idea so your engine cradle is carbon fiber....you can't weld that. Customer: Errr.......? Service Advisor: So we have to replace the engine cradle...which means removing the engine, transaxle, cooling system....Sir, we have to disassemble your engine compartment. Customer: Great...wonderful....fabulous. How much will that cost? Service Advisor: Well...sir....I see by your paperwork here you *JUST* drove out of warranty. Do you by any chance have a personal relationship with your mortgage banker? 2nd mortgages are awesome!

>It’s Decision Time for Ford’s Carbon Fiber Subframe If the result of that decision is positive, it may inspire Ford to apply carbon fiber to other parts of the car...such as engines and transmissions. No thanks. I'll pass and stick with the actual metals for the time being until I'm dead or the ICE is dead - whichever comes first.