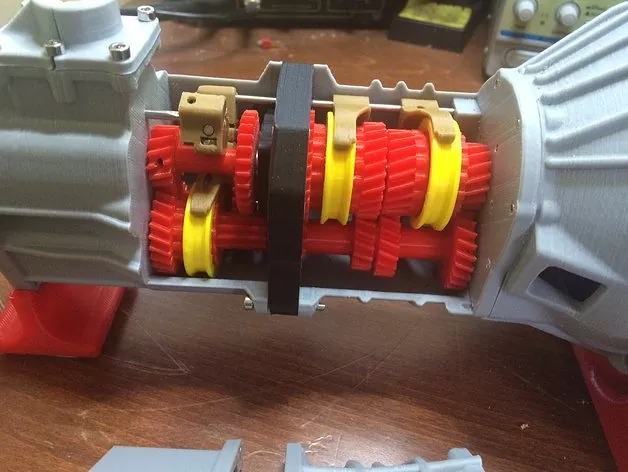

Make Your Own Toyota Transmission At Home (Kind Of)

“The transmission works exactly like most manual transmissions found in any car or truck,” explained Harrell. “However, I can barely explain how it works. It’s fairly hard to grasp unless you assemble one or see an animation of one opened up.”

Last year, I wrote Concours d’Angst as a vision of what small-scale manufacturing might bring to the automotive enthusiast landscape. While I was busy imagining the future, however, someone else was busy making it.

It’s a 3-D printed Toyota transmission made of plastic, for use with a similarly small-scale Toyota 22R engine. You can see it work here:

Obviously, this is neither full-sized nor ready to install in any engine of any type. What makes it important is that it was reverse-engineered by someone who was in no way involved with Toyota, or even with transmissions. As 3-D printing transcends technical limitations and becomes a lingua franca for small-scale fabrication of all types, it will become possible for hobbyists to immediately produce full-sized steel transmissions and other complex parts themselves. It will also become commonplace for those designs to be shared. Imagine a world where you could obtain almost any out-of-stock part for any car through this process, and you’ll see the possibilities.

There will be problems of course — how will you be able to be absolutely sure that the transmission in that hundred-year-old ’77 Celica you just paid two million New Dollars for was machined from tool-grade steel? — but those problems will also be solved as time goes on.

Now, if you’ll excuse me, I’m going to wait for somebody to build me a new four-speed 1990 Fox.

More by Jack Baruth

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Aaron Recently cross shopped both cars. Decided to go with the civic sport. Like the non direct injection 2.0 engine (no long term carbon buildup) and preferred the Hondas transmission over the Toyotas. The civic interior seems much nicer and roomier. Also Honda had many more civics available to choose from vs Toyota. Got almost 2k off sticker. Felt it was the better deal overall. Toyota was not budging on price.

- FreedMike Not my favorite car design, but that blue color is outstanding.

- Lorenzo Car racing is dying, and with it my interest. Midget/micro racing was my last interest in car racing, and now sanctioning body bureaucrats are killing it off too. The more organized it is, the less interesting it becomes.

- Lorenzo Soon, the rental car lots will be filled with Kia's as far as the eye can see!

- Lorenzo You can't sell an old man's car to a young man, but you CAN sell a young man's car to an old man (pardon the sexism, it's not my quote).Solution: Young man styling, but old man amenities, hidden if necessary, like easier entry/exit (young men gradually turn into old men, and will appreciate them).

Comments

Join the conversation

The main thing with 3-D printing is that it changes the economics for producing one-off or small runs of things. It's not going to cause factories to disappear and people to have cars automatically assembled in their garages, anymore than CNC milling did. It will, though, revolutionize the aftermarket in both underhood parts and interior/exterior bling. I want one of those model transmissions...

3D Printing has changed the face of car manufacturing.